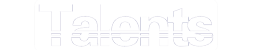

Dust Test Chamber

Specification

The dust test chamber is called “sand and dust test chamber”, which simulates the destructive nature of the sand climate to the product and is suitable for detecting the shell sealing performance of the product. It is mainly used for the test of IP5X and IP6X as specified in the enclosure protection level standard.

Dust Chamber use

Dust Test Chamber is suitable for all kinds of auto parts to do dust and dust test,Test parts include a light.Meter.Electric dust jacket.Steering system.Door lock, etc.

Dust Test Chamber Meet the standard

Dust Test Chamber has a wide range of temperature and humidity control, which can meet the national standard GB4208GB/T2423.37-198

《Basic environmental testing procedures for electric and electronic products》

Dust Test Chamber Test principle

Dust Test Chamber door attached to the window, the door to the lower part of the electrical control area,Simulated sand dust of talc in the lower hopper of the test chamber. Use the of circulating fan and automatic jar will be blown into the upper network studio talcum powder through a 75 micron square hole,The test space form high density dust shape, test specimen.

Dust Test Chamber Structure

1. LCD Touch Screen Programmable Sand and Dust Ingress Testing MachineInner material: Stainless steel (SUS #304)

2. LCD Touch Screen Programmable Dust Proof Test Equipment Outer material: Powder painting steel plate

3. Dust Test Equipment use imported touch screen programmable controller, can control dust blowing motor, dust

vibration and test time.

4. With sealing good chamber door, has lock device and glass observation window.There is lamp and dust brush to

ensure easy observation of inner chamber.

5. Sand and Dust Chamber With strong dust blowing device and vibrator to ensure informity of each blowing.

6. Circulating air supplying device: Frequency converter and high pressure motor to ensure the air volume more

precision.

7. Large diameter strong stainless steel air hose, covered with heating device, can heat and dry the test chamber dust.

8. Dust Test Chamber Anti-explosion handle, easy operation, strurdy and durable.

9. Imported high-precision electronic temperature humidity sensor and air speed sensor.

10. Test sample differential pressure test device, can set pumping rate freely according to sample inquiry.

11. There is a ψ50mm test hole on the left chamber and equipped with port lid and silica gel chock plug. Through this

hole can connect to outer test device.

12. There are casters with brake equipments and fixing foot pad to make the machine easy operation and level adjustment.

13. Sand and Dust Chamber With voltage current indicator, equipped with corresponding sample DC12V power, DC24V / 20 a, interval, continuous power supply adjustable. Dust concentration wind speed regulating function. May control test total time, blow the dust of time interval and blowing dust cycle and sample with the power source of the intermittent time.

14. Vacuum system: Equipped with pressure meter, air filtration, dust dehumidification system, regulating triple pieces,connecting pipe (Vacuum pump should be prepare by customer)

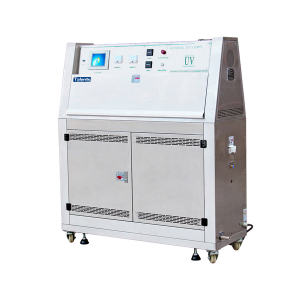

| Model | ZH—SC—500—C | ZH—SC—1000—C | ZH—SC—1500—C |

| inner dia(mm) | 800*800*800 | 1000*1000*1000 | 1000*1000*1500 |

| classification | talcum powder | ||

| time of duration | 2 or 8 hours | ||

| test temp. | RT~70℃ | ||

| test hum. | 45%-75%RH | ||

| Nominal wire diameter of metal screen | 50µm | ||

| Nominal spacing between lines | 75µm | ||

| wind speed | ≥2m/s | ||

| Dust Concentration | 2~4Kg/m³ | ||

| Dust requirements | Meet JIS6 requirements (or corresponding national standards) | ||

| Oscillator period | 0-99H99M99S | ||

| dust setting | Continuous and periodic dust blowing can be selected at any time | ||

| Shell material | High-quality cold-rolled steel plate electrostatic spray | ||

| Inner material | High quality stainless steel precision welding | ||

| thermal insulation material | Superfine glass fiber cotton | ||

| safety protection | Over temperature and over limit alarm protection, power leakage, short circuit, phase loss protection, under voltage protection | ||

| Power supply | AC220/380V±10%,1PH,50/60HZ | ||

| Standard devices | Vacuum pump, gas flow meter, gas source interface, pressure gauge, oil-water separator | ||

| remark |

|

||

Our services

Pre-Sales

1.Technical consultation: test method, laboratory planning and suggestion.

2.Equipment selection: selection scheme, FAQ.

3.Product testing scheme.

In-Sales

- 1.Customer communication and progress report.

- 2.Guidance for pre-installation preparation,equipment commissioning and test run.

- 3.Calibration (when Third Party's verification is required)

After-Sales

- 1.Technical training: operation of equipment, daily maintenance,common fault diagnosis and troubleshooting.

- 2.Scheduled on-site service: Detection of problem as soon as possiblein order to eliminate equipment and anthropogenic hazards. This is toensure long term and stable equipment operation as well as delivery oflatest technical information.

- 3.Technical support: special paid services are provided according tocustomer's needs.

Q1:How to get testing solution and quotation?

A1:If your product requires environmental testing, please contact us to get testing solution and quotation. We will respond to your request within

12 hours.

Q2:How to contact us?

A2:1.Phone: +886 976 590 796

2. E-mail: sales@zh-talents.com

Q3:How to place an order?

A3:If all the details of the products are confirmed,we can draft a contact to you.Also you can send the PO to us by mail.

Q4:How to deal with equipment problems and how to guarantee after-sales service?

A4:If there is problem with the equipment, please contact us and we will reply within 12 hours and arrive at your site within 48 hours.

We have after-sales service offices in Southeast Asia, Taiwan, Hong Kong and other places, and cooperative service providers in other regions.

Q5:How is the product packaged and shipped through logistics?

A5:1. Use export standard wooden boxes for packaging.

2. Choose the most favorable transportation method. Sea freight, air freight, railway, truck transportation, and multimodal transportation.

3. Fast delivery, some models are in stock and will be shipped in 1-3 days.