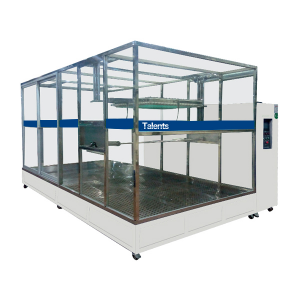

Salt Spray Test Chamber

Specification

The salt spray test chamber is mainly used for surface treatment of various materials, including paint, electroplating, inorganic and hundred-faced coatings, anode treatment, anti-rust oil and other anti-corrosion treatments, and the corrosion resistance of its products is tested.

Salt Spray Test Chamber summary

This 60L Humidity And Temperature Salt Spray Corrosion Test Chamber is a machine that the testing condition is the closest to the natural environment,it simulated condition that more often meet at natural environment, and then deteriorated the natural environment to be tested, such as the salt spray, dry, wet, room temperature, low temperature environment,it can be tested in any order or individually tested.

Salt Spray Test Chamber Applicable Industry

This Humidity And Temperature Salt Spray Corrosion Test Chamber is tested the corrosion resistance capacity of products, which stay in the intense change environment, such as automobile parts, aviation equipment, photographic equipment, building materials, electricity, electrical and electronic systems

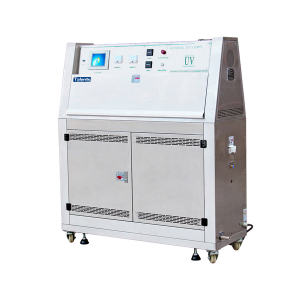

Salt Spray Test Chamber Features

1.Salt spray test chamber With color touch screen LCD controller (Japan OYO U-8256P), which can record the testing curves.

2.Control mode: temperature, humidity, temperature and humidity can do alternating control by the program.

3.Program Group Capacity: 140Pattern (Group) 1400Step (above) each program can be set up to Repest99 segment.

4.Each executive mode time can be arbitrarily set 0-999 hours, 59 minutes.

5.Each group can be arbitrarily set the cycle of 1-999 .

6.Has the power memory function, recovery after power continue to perform the not completed the test.

7 . interface RS232 connect with computer.

Salt Spray Test Chamber Corresponding standard

1.GB/T 20854-2007 Dry and wet salt spray test

2.ISO14993-2001 Dry and wet salt spray test

|

Model |

ZHL-60-SS |

ZHL-90-BS |

ZHL-120-NS |

ZHL-160-NS |

ZHL-200-NS |

|

| Inside Size W*D*Hcm | 60*45*40 | 90*60*50 | 120*85*50 | 160*100*55 | 200*120*60 | |

| Outside Size W*D*Hcm | 113*63*107 | 146*91*128 | 220*120*145 | 260*145*155 | 300*165*160 | |

|

Temp |

Test |

NSS.ACSS 35℃±1℃/CASS 50℃±1℃ |

||||

| Air |

NSS.ACSS 47℃±1℃/CASS 63℃±1℃ |

|||||

| Power supply |

AC220±10V 1¢20A |

AC1¢220V 30A or AC3¢380V |

||||

| Volume | 108L | 270L | 480L | 800L | 1440L | |

| Water tank | 15L | 25L |

40L |

|||

| remark | 1.Can be customized according to customer needs

2.Specific parameters and specifications are subject to the quotation |

|||||

Our services

Pre-Sales

1.Technical consultation: test method, laboratory planning and suggestion.

2.Equipment selection: selection scheme, FAQ.

3.Product testing scheme.

In-Sales

- 1.Customer communication and progress report.

- 2.Guidance for pre-installation preparation,equipment commissioning and test run.

- 3.Calibration (when Third Party's verification is required)

After-Sales

- 1.Technical training: operation of equipment, daily maintenance,common fault diagnosis and troubleshooting.

- 2.Scheduled on-site service: Detection of problem as soon as possiblein order to eliminate equipment and anthropogenic hazards. This is toensure long term and stable equipment operation as well as delivery oflatest technical information.

- 3.Technical support: special paid services are provided according tocustomer's needs.

Q1:How to get testing solution and quotation?

A1:If your product requires environmental testing, please contact us to get testing solution and quotation. We will respond to your request within

12 hours.

Q2:How to contact us?

A2:1.Phone: +886 976 590 796

2. E-mail: sales@zh-talents.com

Q3:How to place an order?

A3:If all the details of the products are confirmed,we can draft a contact to you.Also you can send the PO to us by mail.

Q4:How to deal with equipment problems and how to guarantee after-sales service?

A4:If there is problem with the equipment, please contact us and we will reply within 12 hours and arrive at your site within 48 hours.

We have after-sales service offices in Southeast Asia, Taiwan, Hong Kong and other places, and cooperative service providers in other regions.

Q5:How is the product packaged and shipped through logistics?

A5:1. Use export standard wooden boxes for packaging.

2. Choose the most favorable transportation method. Sea freight, air freight, railway, truck transportation, and multimodal transportation.

3. Fast delivery, some models are in stock and will be shipped in 1-3 days.