Vertical Vibration test system

Specification

Frequency range (Hz): 2~3000

Maximum sinusoidal force (kg): 300kgf

Maximum random force (kg): 300kgf

Maximum shock force (kg): 600kgf

Maximum acceleration (g): 100

Maximum displacement (mm p-p): 76

Maximum velocity: 2.0 (m/s)

Payload: 100kg

Optional model: 300kg, 600kg, 1000kg, 2000kg, 3000kg, 4000kg, 5000kg, 6000kg, 10000kg, 20000kg (Include and above).

Customization options: vertical head expander, horizontal slip table, vibration controller, auxiliary devices, etc.

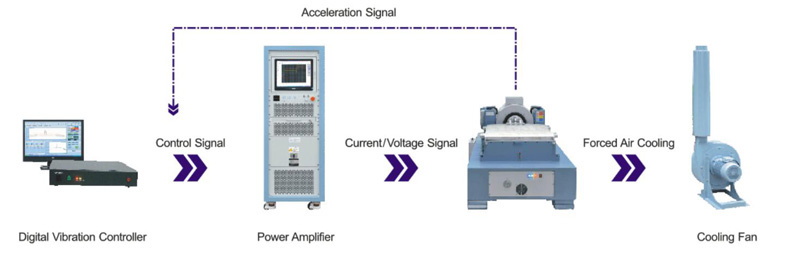

Working Principle of Vibration table

The Vibration table working principle of the electromagnetic vibration exciter is similar to a loudspeaker whereby electrical

conductor is moved by the action of electromagnetic force in the magnetic field. The force to accelerate the

moving part is generated by the balance between driving current and magnetic flux. Therefore, by

controlling the driving current, one can control the vibration generator.

The Vibration Test System maximum acceleration level of the electromagnetic vibration exciter is determined by the maximum

current and the loading. At low frequency, displacement of moving part is restricted such that the

acceleration will not reach high level. The resonance frequency of the moving element is set higher

than the upper limit of the frequency range.

The Electromagnetic vibration table performance of vibration generator can be reflected by the chart that displays the maximum

acceleration under different frequencies. By using a log-log plot, the restriction of displacement

can be expressed by a straight line with slope of 6 dB/octave.

Vibration table Features

1. Electromagnetic vibration table Rugged suspension system and linear motion guiding, strong carrying capacity, good guiding functions, high stability.

2. Load center airbag with high static stiffness and low dynamic stiffness, strong carrying capacity, perfect performance on amplitude variation.

3. vibration test chamber High efficiency D class power switching, 3-sigma peak current, low power consumption and minimum harmonic distortion.

4. Quick self-diagnosis with safety interlock, high safety reliability.

5. Airbag shock isolation device for vibration platform without the need of additional. foundation, perfect reproduction of vibrational wave and reduction in vibration transmittance.

6. Horizontal and vertical expansion platforms for different applications.

7. Simple controller operation.

The general formula for calculating force vector of vibration systems

Force(N) = Mass(kg) x Accelration( m/s² or g) F=MA

Mass = Shaker Armature + device under test + fixture (vertical table/slip table with driver bar)

Vibration Test System for Automotive parts,vibration table,vibration machine,Electromagnetic vibration table,Vibration Test Chamber|TALENTS

|

Model |

ZH203 |

ZH206 |

ZH210 |

ZH220 |

ZH232 |

ZH240 |

ZH250 |

ZH260 |

|

Frequency range(Hz) |

1-2500 |

1-3000 |

1-3000 |

1-3000 |

1-3000 |

2-2500 |

1-2500 |

1-2700 |

|

Maximum excitation force Kg(KN) |

300(2.94) |

600(5.88) |

1000(9.8) |

2200(21.56) |

3200(31.36) |

4000(39.2) |

5000(49) |

6000(58.8) |

|

Maximum displacement(mmp-p) |

40 |

50.8 |

50.8 |

50.8 |

50.8 |

50.8 |

50.8 |

50.8 |

|

Maximum acceleration(g) |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Maximum speed(cm/s) |

200 |

200 |

200 |

200 |

200 |

200 |

200 |

200 |

|

Payload(kg) |

120 |

200 |

200 |

400 |

400 |

500 |

800 |

1000 |

|

Dynamic coil quality(kg) |

3 |

6 |

10 |

22 |

32 |

40 |

50 |

50 |

|

Dynamic coil diameter(mm) |

Φ150 |

Φ200 |

Φ240 |

Φ320 |

Φ400 |

Φ440 |

Φ445 |

Φ445 |

|

Cooling method |

Forced air cooling |

|

|

|

|

|

|

|

|

Weight of exciter(kg) |

460 |

920 |

1100 |

1700 |

2500 |

2500 |

3500 |

4500 |

|

Exciter size(mm) |

750*560*670 |

800*600*710 |

845*685*840 |

1200*870*1100 |

1270*980*1140 |

1400*980*1140 |

1600*1120*1340 |

1650*1150*1280 |

|

Power amplifier weight(kg) |

250 |

320 |

350 |

500 |

550 |

600 |

800 |

1000 |

|

Power amplifier size(mm) |

880*580*1150 |

880*580*1270 |

880*580*1690 |

880*580*1520 |

910*620*1550 |

910*620*2000 |

910*620*2000 |

910*620*2000 |

|

Total power(KW) |

9 |

20 |

25 |

35 |

56 |

56 |

75 |

75 |

Our services

Pre-Sales

1.Technical consultation: test method, laboratory planning and suggestion.

2.Equipment selection: selection scheme, FAQ.

3.Product testing scheme.

In-Sales

- 1.Customer communication and progress report.

- 2.Guidance for pre-installation preparation,equipment commissioning and test run.

- 3.Calibration (when Third Party's verification is required)

After-Sales

- 1.Technical training: operation of equipment, daily maintenance,common fault diagnosis and troubleshooting.

- 2.Scheduled on-site service: Detection of problem as soon as possiblein order to eliminate equipment and anthropogenic hazards. This is toensure long term and stable equipment operation as well as delivery oflatest technical information.

- 3.Technical support: special paid services are provided according tocustomer's needs.

Q1:How to get testing solution and quotation?

A1:If your product requires environmental testing, please contact us to get testing solution and quotation. We will respond to your request within

12 hours.

Q2:How to contact us?

A2:1.Phone: +886 976 590 796

2. E-mail: sales@zh-talents.com

Q3:How to place an order?

A3:If all the details of the products are confirmed,we can draft a contact to you.Also you can send the PO to us by mail.

Q4:How to deal with equipment problems and how to guarantee after-sales service?

A4:If there is problem with the equipment, please contact us and we will reply within 12 hours and arrive at your site within 48 hours.

We have after-sales service offices in Southeast Asia, Taiwan, Hong Kong and other places, and cooperative service providers in other regions.

Q5:How is the product packaged and shipped through logistics?

A5:1. Use export standard wooden boxes for packaging.

2. Choose the most favorable transportation method. Sea freight, air freight, railway, truck transportation, and multimodal transportation.

3. Fast delivery, some models are in stock and will be shipped in 1-3 days.